Framing Safety Across Industries

Framing is a fundamental component in construction, general industry, and railroad operations, forming the backbone of structural integrity. Whether building homes, commercial spaces, or supporting infrastructure, framing safety is crucial to prevent accidents and ensure compliance with regulatory standards. This journal explores why framing is important across industries, referencing OSHA standards such as 29 CFR 1926, 29 CFR 1910, and other relevant guidelines. It also provides a comprehensive look at best practices that reduce risks while maintaining productivity.

The Importance of Framing Safety

Framing forms the structural foundation of any construction, making safety a top priority. OSHA outlines specific regulations regarding framing activities to prevent falls, material failures, and other accidents. In construction, OSHA 29 CFR 1926.500 covers the scope and application of safety requirements, ensuring that all workers are protected during framing tasks. Proper training, equipment selection, and adherence to safety protocols are essential to avoid injuries and maintain a safe working environment.

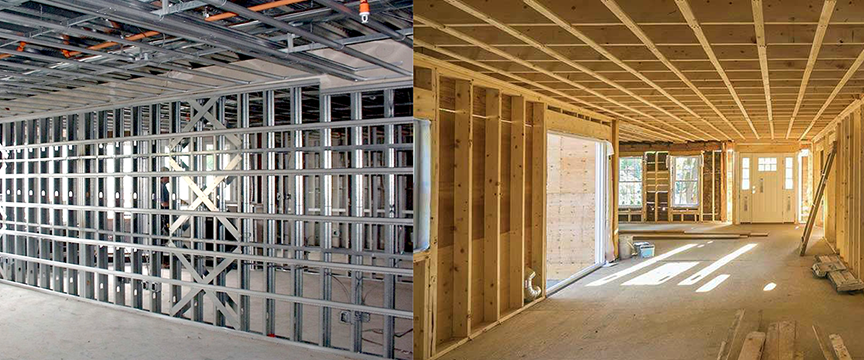

Framing in Construction

In construction, framing involves the assembly of structural elements like walls, floors, and roofs. OSHA’s 29 CFR 1926.501 and 1926.502 highlight the need for fall protection, personal protective equipment (PPE), and regular inspections of framing materials. The dynamic nature of construction sites means that hazards can change rapidly, requiring consistent adherence to safety protocols. Effective communication and teamwork are critical, ensuring that framing tasks are executed without compromising worker safety.

Framing in General Industry

General industry settings may involve framing activities in the construction of facilities, equipment housing, or support structures. OSHA 29 CFR 1910.140 mandates the use of personal fall protection systems when working at heights. In addition, OSHA emphasizes the importance of using appropriate tools and conducting regular inspections of framing materials to prevent structural failures. Training programs play a pivotal role in helping workers understand and comply with these safety standards.

Framing in the Railroad Industry

The railroad industry presents unique framing challenges, especially in building support structures for tracks, bridges, and stations. The Federal Railroad Administration (FRA) and OSHA have established guidelines, including 29 CFR 1926.503, which mandates training requirements for those working at heights. Framing in this industry requires precise measurements, the use of specialized materials like carbon steel and galvanized metal, and stringent inspection routines to prevent catastrophic failures.

Integrating Framing Safety into the Four Key Areas of Safety

Framing safety is integral to hazard identification, risk assessment, incident prevention, and emergency preparedness. OSHA guidelines ensure that potential hazards are recognized early, risks are minimized, and incidents are prevented through robust safety measures. Emergency preparedness, including swift response plans and readily available first aid, further reinforces the importance of a proactive approach to framing safety.

Common Safety Practices for Framing Safety

To maintain safe framing practices, consider the following strategies:

- Comprehensive Training: Ensure all workers are adequately trained in framing procedures and fall protection measures (OSHA 29 CFR 1926.503).

- Regular Equipment Inspections: Inspect all framing tools and materials for wear, damage, and defects before use (OSHA 29 CFR 1926.502(d)(21)).

- Use of PPE: Utilize proper PPE, including hard hats, safety glasses, gloves, and harnesses when working at heights (OSHA 29 CFR 1926.95).

- Fall Protection Systems: Implement guardrails, safety nets, and full-body harnesses when working more than six feet above ground level (OSHA 29 CFR 1926.501).

- Clear Communication: Maintain open lines of communication among workers to ensure everyone is aware of potential hazards and safety procedures (OSHA 29 CFR 1910.1020).

- Tool Maintenance: Keep all tools clean, functional, and in good repair according to manufacturer guidelines (OSHA 29 CFR 1926.502(d)).

- Worksite Organization: Keep work areas clean and free from obstructions to reduce the risk of trips, slips, and falls.

- Proper Lighting: Ensure adequate lighting in all work areas to prevent accidents and ensure precise work.

- Safety Audits: Conduct regular safety audits to identify and mitigate any risks related to framing activities.

- Emergency Preparedness: Have clear emergency response procedures in place, and conduct drills to ensure readiness in case of incidents.

Conclusion

Framing safety is not just a regulatory requirement; it is a fundamental aspect of maintaining structural integrity and protecting workers from potential hazards. By following established standards and integrating best practices, organizations can create safer work environments and ensure the successful completion of framing projects across industries. A commitment to training, proactive inspections, and a culture of safety is essential for minimizing risks and enhancing workplace safety.

References

Standard for Scope, Application, and Definitions Applicable to this Subpart. OSHA 29 CFR § 1926.500 Subpart M (2023).

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.500

Standard for Duty to Have Fall Protection. OSHA 29 CFR § 1926.501 Subpart M (2024).

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.501

Standard for Fall Protection Systems Criteria and Practices. OSHA 29 CFR § 1926.502 Subpart M (2024).

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.502

Standard for Training Requirements. OSHA 29 CFR § 1926.503 Subpart M (2024).

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.503.

Standard for Personal Fall Protection Systems. OSHA 29 CFR § 1910.140 Subpart I (2017).

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.140

Standard for Criteria for Personal Protective Equipment. OSHA 29 CFR § 1926.95 Subpart E (2023).

https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.95

Standard for Access to Employee Exposure and Medical Records. OSHA 29 CFR § 1910.1020 Subpart Z (2019).

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.1020