Real-Time Monitoring and Reporting: Strengthening Safety and Compliance Across Industries

In high-risk sectors such as construction, transportation, manufacturing, and railroads, delayed reporting can lead to serious safety violations and operational disruptions. Traditional safety systems often fall short in delivering timely information to the people who need it most site supervisors, safety officers, and executive teams leaving both workers and companies exposed. Real-time monitoring and reporting capabilities offer a transformative solution by ensuring hazards are identified, communicated, and addressed immediately, helping organizations avoid regulatory penalties and reputational damage while protecting their workforce.

At Key Safety LLC, our mission is to simplify compliance, increase transparency, and foster a proactive safety culture. Our consulting services empower clients to move from paper-based systems to live digital platforms, allowing safety teams to act swiftly based on real-time data that aligns with evolving OSHA, DOT, and ISO standards.

Many organizations still rely on slow, manual processes that delay hazard recognition and limit timely corrective action. Paper logs and disconnected databases obscure the full scope of risks particularly in multi-site or contractor-heavy operations leading to underreporting and preventable incidents. As regulatory pressures intensify, these inefficiencies become critical liabilities.

Real-time monitoring changes everything. By combining sensors, mobile apps, and digital dashboards, companies can record incidents, near-misses, and environmental readings instantly. This real-time data stream enhances incident response, supports continuous improvement, and prevents repeated violations. For example, wearable devices can immediately notify teams of falls, elevated temperatures, or hazardous exposure, enabling faster containment and first aid. Such technologies elevate safety from a retrospective compliance task to a dynamic strategic advantage.

Regulators are also demanding timely, accurate reporting. According to the Occupational Safety and Health Administration (Top 10 Most Frequently Cited Standards, 2024) inaccurate or delayed incident logs remain among the most cited violations in recent years. Digital systems with built-in time stamps, geo-tags, and approval workflows help organizations meet these compliance requirements and avoid fines.

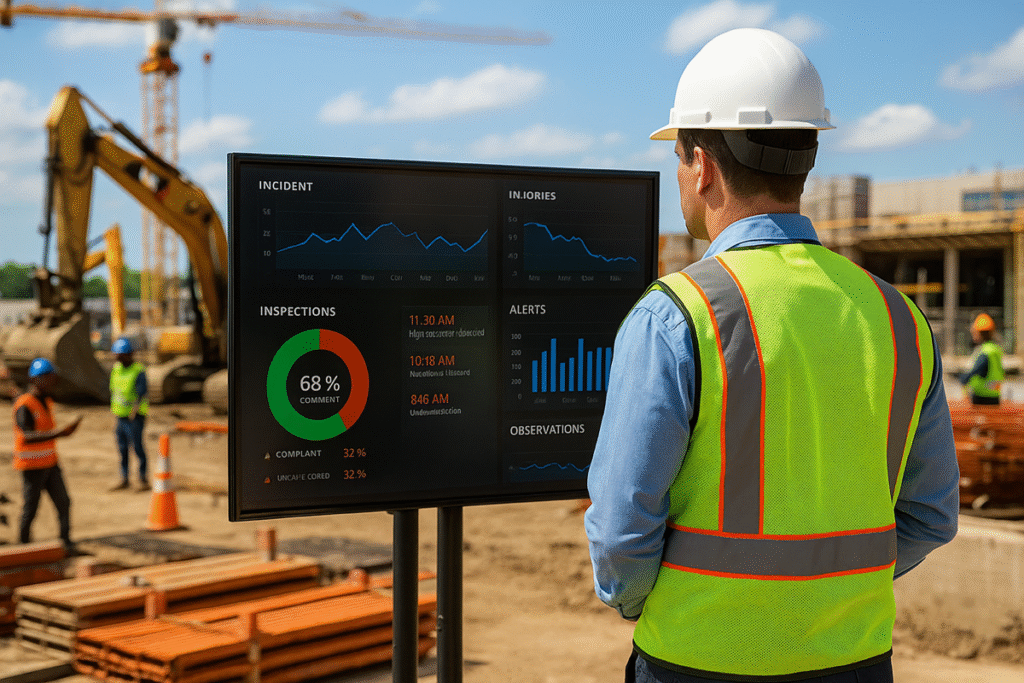

Executives benefit from this live data dashboards can display key performance indicators, incident trends, and open corrective actions across projects. Real-time visibility supports better resource deployment and predictive risk management. Safety leaders can now act proactively instead of reacting to crises, which boosts operational confidence and resilience.

In construction, platforms like OpenSpace and Smartvid.io stream live site video to identify unsafe behaviors, missing barriers, and housekeeping issues all updated in real time. This is essential under OSHA’s Multi‑Employer Citation Policy, which holds general contractors responsible for site-wide compliance (Multi-Employer Citation Policy, 1999). Shared digital platforms enable faster issue resolution and collaborative accountability.

Transportation fleets also benefit from real-time tools. Electronic Logging Devices and telematics systems like Samsara or Geotab track driver behavior, vehicle condition, and compliance with DOT hours‑of‑service mandates. These systems promptly flag speeding, excessive idling, or harsh braking, helping companies proactively enforce safety standards and reduce accident risk.

Manufacturing plants face dual challenges: safety and productivity. Sensor systems such as Siemens MindSphere or Honeywell Forge monitor machine vibrations, temperature, and performance indicators. Predictive alerts prevent equipment breakdowns that could cause accidents or unplanned downtime supporting ISO 45001’s emphasis on proactive risk control (Occupational health and safety management systems, 2024).

Railroad operations rely heavily on real-time reporting. Systems like Positive Train Control (PTC) continuously track train locations, speed compliance, and track integrity to prevent collisions and derailments part of the Federal Railroad Administration’s mandated digital oversight program (Railroad Safety, 2025).

Real-time monitoring also strengthens safety culture. When workers witness that reported hazards are addressed promptly and transparently, their trust and engagement grow. Mobile apps that allow field staff to submit photos and brief notes streamline reporting and encourage participation, increasing hazard visibility and reinforcing a safety-first mindset.

Key Safety LLC supports clients in designing integrated, real-time safety ecosystems. We evaluate current processes, recommend appropriate platforms, conduct training, and align workflows with regulatory standards like Safety and Health Regulation for Construction (Safety Training and Education, 2015) We also build contingency protocols tailored to South Florida’s hurricane seasons linking real-time weather alerts from FEMA’s Integrated Public Alert and Warning System (IPAWS) into operational procedures (Integrated Public Alert & Warning System, 2025) to guide evacuations and site shutdowns.

But rolling out real-time systems goes beyond hardware and software it demands clear procedures, defined roles, and sound data governance. Key Safety LLC helps establish digital inspection forms, corrective-action protocols, and training compliance tracking all centralized and accessible live which reduces administrative workload and strengthens accountability.

As workplace risks evolve and regulations become stricter, real-time monitoring and reporting have become essential, not optional. These capabilities protect lives, ensure compliance, and improve operational efficiency. Companies that invest in real-time safety tools today are setting new standards for tomorrow. With expert support, strong systems, and a commitment to transparency, real-time safety is not just achievable it’s here now.

References

Federal Emergency Management Agency. (2025). Integrated public alert and warning system (IPAWS). https://www.fema.gov/emergency-managers/practitioners/integrated-public-alert-warning-system

Standard for Safety Training and Education. OSHA 1926.21 Subpart C (2015) https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.21

Federal Railroad Administration. (2025). Railroad safety. https://railroads.dot.gov/railroad-safety

International Organization for Standardization. (2023). ISO 45001:2018 – Occupational health and safety management systems. https://www.iso.org/standard/63787.html

Occupational Safety and Health Administration. (1999). Multi-employer citation policy (CPL 02-00-124). https://www.osha.gov/enforcement/directives/cpl-02-00-124

Occupational Safety and Health Administration. (2024). Top 10 most frequently cited OSHA standards.https://www.osha.gov/top10

Comments: